Antenna Miscellany

[Home]

[Shack]

[Projects]

[Tech Topics]

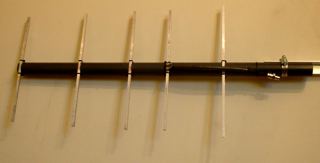

This page is for antennas and antenna accessories that don't get a full writeup, at least yet. First up is the VHF antenna stack that I built for the June VHF QSO Party 2006. It required an additional clamp on the balcony mast.

The VHF contest antennas

The antennas are the six meter Moxon, a 2m five element yagi and a 4 element 435MHz yagi, which has decent SWR and pattern at 432 as well. The antennas were designed with QuickYagi by WA7RAI and tweaked in EZNEC for best pattern. The 2m boom is 80/20 from McMaster Carr and makes it easy to set the element spacing, and to do some empirical tweaking if necessary. The separation of the 435 MHz yagi from the 2m yagi was set for maximum front-to-back of the 435MHz unit. The 2m yagi doesn't even notice the presence of the 70cm antenna. There are two runs of coax, one for the 50MHz Moxon and one for the 2m/70cm antenna, split by an MFJ diplexer mounted on the boom. I have about 2dB of measured line loss on 435MHz.

The array clears the roof by about 4 feet.

I've modeled the whole stack in EZNEC and found minimal interaction among the antennas and the environment. The six meter pattern distortion is still present, but the HF antenna and metal balcony roof don't affect the 2m antenna much, and the 70cm none at all. I worked many stations on 2m and 432 in the June QSO party and it seems to perform quite well. Of course, I was working big guns but I seemed to be able to make contact with well equipped stations out to as much as 240 miles. I am not sure of the propagation mode, whether it was troposcatter or tropo ducting. The 2m/70cm beam will also work well for close-to-the-horizon LEO work I think. I've tried it before, but when I didn't have a rotator, it was difficult going! The rotator has a gearmotor with a belt drive to a pinion and an internal ring gear mounted on the mast. The ring and pinion are taken from a junked General Radio 50-250MHz signal generator's reduction drive; it's somehow appropriate...

In this shot you can see the extra stainless mast bracket.

Here's a 5 element yagi for 440MHz. I designed it using Quickyagi by WA7RAI. I used a milling machine to cut the slots in the boom. Not so practical for home use but you could just use some square nonconductive stuff and strap 'em on. A bead balun made of FT-50-43 toroids over coax keeps currents off the coax shield. I usually use this one mounted on a tripod on the balcony. I won't include details, just download the program (or your favorite yagi designer) and make one for yourself. Mine's got 10dB gain, about 20dB F/B ratio.

440MHz yagi with 1/4" square elements and PVC boom.

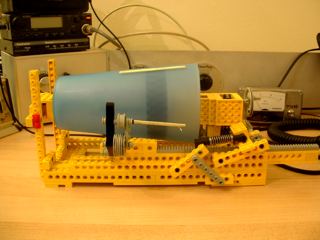

A big part of using invisible wire antennas for HF is the necessity to frequently reinstall them. 30ga. magnet wire is not the pinnacle of wire strength, so my dipole often loses a leg on a gusty day. A slingshot and weights makes it easy to put the wires back, though I've had to do it very late at night so I can play out the wire onto the ground two floors down. It won't come off an ordinary spool fast enough to shoot it out. I think it was a few years ago in QST or CQ that someone suggested putting a few strips of double stick tape on a drinking glass and winding wire onto it. It spools off as the weight flies, and it's easy to get 100ft plus on a big plastic glass. Well, except for the fact that the first time I did it, it took me a half hour to wind the wire on the glass. So I built this:

My Lego® wire winder for a drinking glass wire launching spool.

The small black arm sticking upward in the foreground is the wire guide, and it's attached to the long gear rack. A pinion driven through a couple of stages of gear reduction drives the rack from the wide end of the glass to the narrow end as the glass rotates. The crank visible to the right in the above picture is what I'm currently using to drive the glass rotation. I played with the gear reduction to wind a good tight pitch to spool on as much wire as possible without (much) overlap. The left end support for the glass is removable to get the glass out; the red blocks remind me where to put it back. The "shock absorber" spring part has two uses: the pinion does not fit otherwise, the spring allows it to sit in a proper meshed position, and additionally, the pinion can be lifted off the rack for a fast reset of the wire guide arm.

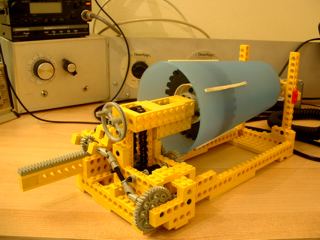

Another view of the Lego® wire spooler showing more of the gears.

The winder works pretty well. I have an adapter to hold the glass on the end of a microphone stand while launching the wire, and now I can wind the glass full of 100ft of wire in just a couple of minutes. The winder does not tolerate much tension on the wire, so I first wind it off the normal spool onto an old bicycle wheel. The wheel turns very freely with even a tiny amount of tension, and as such, I can turn the crank quite fast. Some overlap is inevitable when going fast, but it seems that it's not really a problem when spooling out the wire, as long as it doesn't cross back over more than about two turns.